BC-600 high speed 8 cavity PET bottle blow molding machine

BC-600 high speed 8 cavity PET bottle blow molding machine

Taizhou Huangyan Dingren Plastic Machinery Factory is a manufacturer specializing in the development and production of blow molding machines and molds. The company has strong technical force, sophisticated production equipment, advanced testing instruments and a sound management system. Dingren blow molding machine is a kind of blow molding machine developed by our company with simple operation, high success rate, wide applicability, reliability and stability. It adopts famous and high-quality products from Germany, Japan, Taiwan and other domestic and foreign countries. The control system is mainly controlled by ordinary circuit P program control. It is designed with high efficiency, high precision, convenient maintenance, safe and reliable, beautiful and durable. The product can guarantee your production development, and the enterprise is thriving.

Parameter Description

Specifications

BC A series fully automatic pet blow molding machine,It can blow bottles as below: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

A. Settings:

a).PLC ------------SIEMENS(GERMANY)

b).Valve for action------------SMC(KOREA)

c).Valve for blowing-----------FESTO(GERMANY)

d).Cylinder(stretch and clamping)-------------FESTO(GERMANY)

e).Controller of preform transfer---------------Servo motor National(JAPAN)

f).Other electric parts are all world-famous brands

B. Machine Features:

B.1. High Speed: 2000BPH(2-cavity), 4000BPH(4-cavity), 6000BPH(6-cavity), 8000BPH(8-cavity);

B.2. High Stability: Stable performance with advanced PLC;

B.3. High Efficiency: Under the environment of sharp penetrability and swift distribution, the preform will be rotated by itself ;

B.4. High-level Automation: Preforms will be carried automatically by automatic conveyor;

B.5.High Adjustability: When preheat various preforms, just need to adjust the light tube and the length of the reflecting board on preheating area.

B.6. High Security: The automatic-locking apparatus in each mechanical action, which will make all the procedures turn into a state of safety;

B.7. High Innovation:

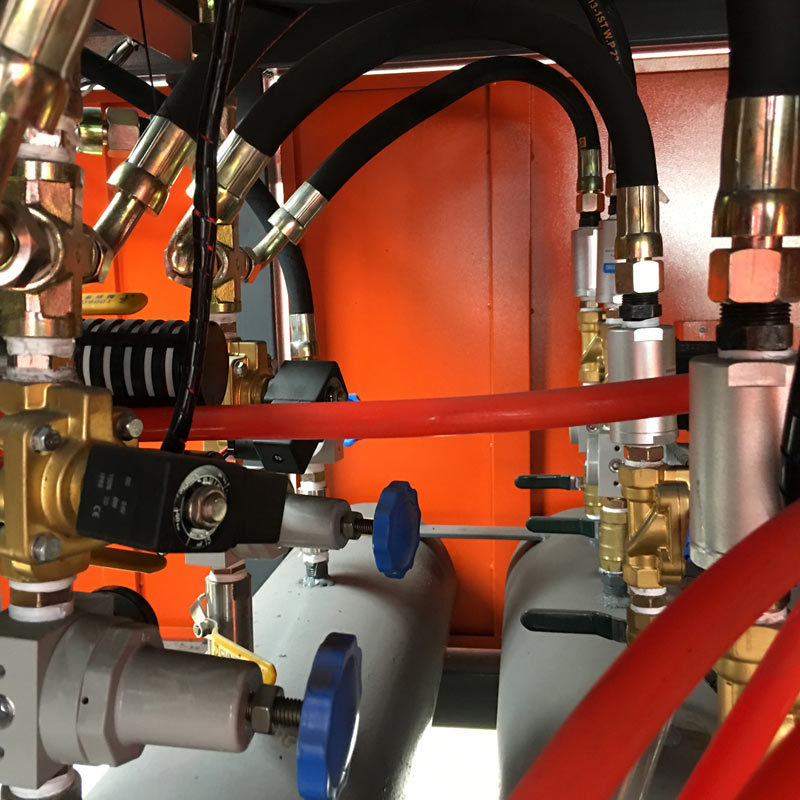

1),Cooperation with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine;

2),Unique design of the position of valve to make the air pressure diagram of the machine would be easier to understand;

3),Strong clamping force with high pressure and double crank links to lock the mold tightly;

4),Ideal effect of the chilling with the chilling system;

B.8.High environmental protection: No contamination and low noise with the air cylinder to drive the action instead of the oil pump;

B.9. High convenience:

1),Two ways of operating: automatic and manual;

2),Low cost (lower consumption of electricity,air and water), high efficiency, easy operation, easy maintenance, etc, with automatic technological process;

3), Easy installation and starting;

B.10.High Quantity: Low rejection rate: less than 0.2 percent.

| TYPE | Item | BC-600 -8 |

| | NO. of cavities | 8 cavities |

| Theoretical productive capacity | 8000-12000pcs/hr | |

| Max.volume of container | 0.6L | |

| Max.neck size of container | 38mm | |

| Max. container diameter | 65mm | |

| Max.height of container | 260mm | |

| | Lamp Quantity | 48pcs |

| Max.heating power | 128kw | |

| Total power | 128kw | |

| Actual consumption of electricity | 23kw | |

| | Working pressure | 0.7-0.9mpa |

| Low pressure power consumption | 1800Ltr/min | |

| Blowing pressure | 25-35kg/c㎡ | |

| High pressure power consumption | 2500-3200 Ltr/min | |

| | Working pressure | 5-6 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000 kca/hr | |

| Chilled water flow | 65 Ltr/min | |

| | Dimension of machine | 5.5*2.1*2.1(m) |

| Weight of machine | 6.0 ton |